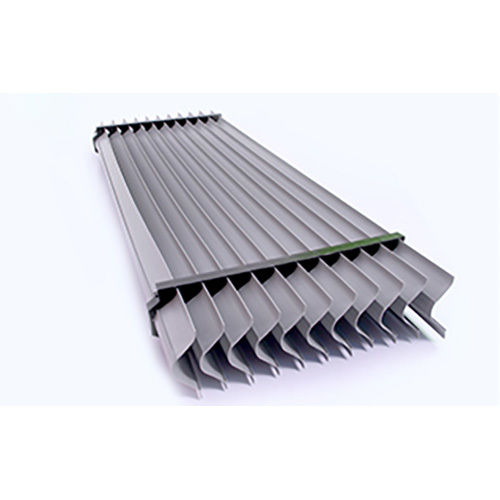

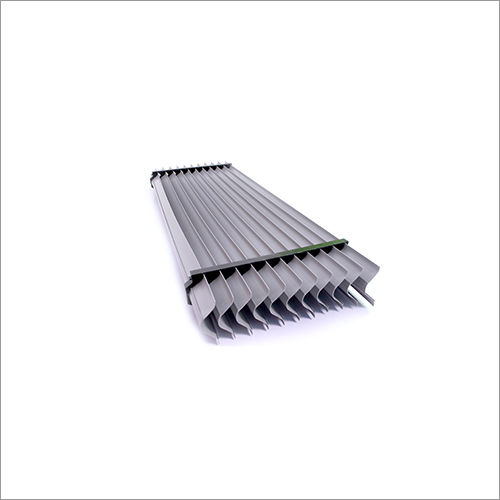

Double Wall Drift Eliminators

60 INR/Square Meter

Product Details:

- Application Cooling towers

- Material PVC/PP

- Condition New

- Usage Industrial

- Type Double Wall Drift Eliminators

- Color Sliver

- Warranty 1 Year

- Click to view more

X

Double Wall Drift Eliminators Price And Quantity

- 60 INR/Square Meter

- 20000 Square Meter

Double Wall Drift Eliminators Product Specifications

- Sliver

- 1 Year

- Industrial

- PVC/PP

- Double Wall Drift Eliminators

- Cooling towers

- New

Double Wall Drift Eliminators Trade Information

- 1000 Square Meter Per Month

- 1 Week

Product Description

Capitalise on the grand design and radiant efficiency of our Double Wall Drift Eliminators, crafted with enviable precision for cooling towers. In demand across industrial sectors, these silver-toned solutions, available in new condition, are made using robust PVC/PP materials, ensuring longevity and performance. Spotlight your business with this innovative application, backed by a 1-year warranty for peace of mind. As an exporter, manufacturer, and supplier in India, we empower industries to minimise water loss, elevate operational standards, and optimise cooling tower performance for enviable results.

Double Wall Drift Eliminators: Precision for Industrial Cooling

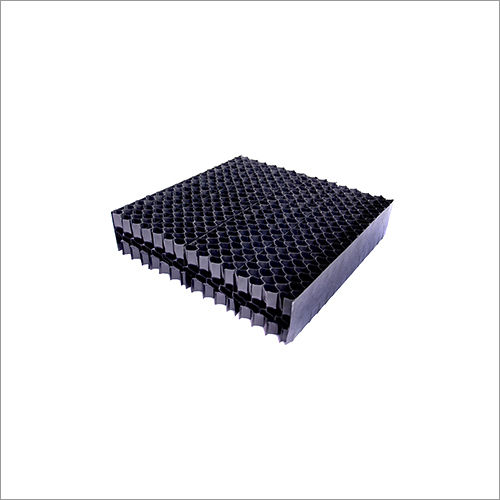

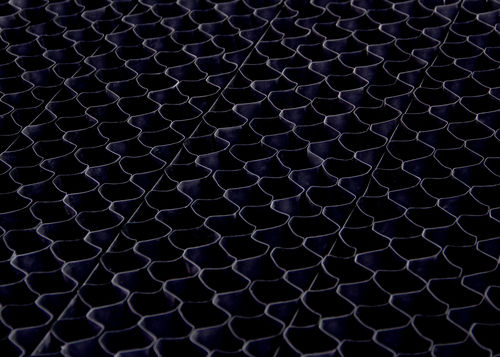

Double Wall Drift Eliminators offer unrivalled efficiency on application surfaces such as fill packs and air intake areas within industrial cooling towers. Designed for places including factories, chillers, and power plants, these drift eliminators must be installed along airflow paths to maximise water retention. The direction of use involves careful placement to ensure optimal drift reduction, making them ideal for both new and retrofit cooling tower projects.

Packing, Dispatch, and Sample Supply Details

Packing & Dispatch is conducted with precision, ensuring all Double Wall Drift Eliminators are securely packaged to protect their radiant finish during transit. Samples are available upon request for customer evaluation. With competitive sale prices and robust supply ability, these products are delivered seamlessly across regions, guaranteeing rapid turnaround and customer satisfaction for every order placed.

Double Wall Drift Eliminators: Precision for Industrial Cooling

Double Wall Drift Eliminators offer unrivalled efficiency on application surfaces such as fill packs and air intake areas within industrial cooling towers. Designed for places including factories, chillers, and power plants, these drift eliminators must be installed along airflow paths to maximise water retention. The direction of use involves careful placement to ensure optimal drift reduction, making them ideal for both new and retrofit cooling tower projects.

Packing, Dispatch, and Sample Supply Details

Packing & Dispatch is conducted with precision, ensuring all Double Wall Drift Eliminators are securely packaged to protect their radiant finish during transit. Samples are available upon request for customer evaluation. With competitive sale prices and robust supply ability, these products are delivered seamlessly across regions, guaranteeing rapid turnaround and customer satisfaction for every order placed.

FAQs of Double Wall Drift Eliminators:

Q: How do Double Wall Drift Eliminators function in cooling towers?

A: Double Wall Drift Eliminators work by capturing and redirecting water droplets that would otherwise escape through the cooling towers exhaust. This process ensures minimal water loss and promotes efficient operation.Q: What is the installation process for these drift eliminators?

A: Installation involves placing the drift eliminators within the cooling towers air stream, typically above or among fill packs. Positioning them correctly is vital to achieving maximum drift reduction and efficient performance.Q: Where can Double Wall Drift Eliminators be used?

A: They are primarily used in industrial cooling towers at locations like factories, power generation plants, refineries, and HVAC systems, wherever water conservation and air quality are important.Q: What material options are available for Double Wall Drift Eliminators?

A: Our drift eliminators are available in PVC, PP, and other durable materials, allowing clients to select the type that best suits their application needs and environmental conditions.Q: What benefits come with using Double Wall Drift Eliminators?

A: Benefits include reduced water loss, improved cooling tower efficiency, enhanced environmental compliance, and cost savings from minimising operational expenses and water usage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese