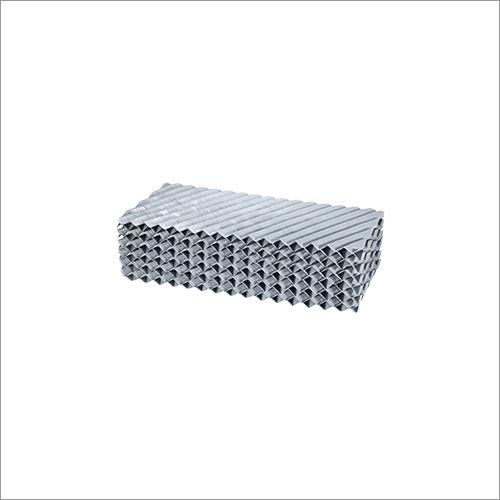

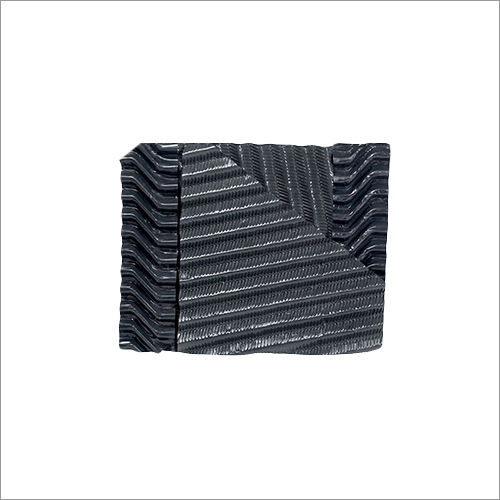

Pvc Film Fills

Product Details:

- Application Industrial

- Type Pvc Film Fills

- Product Type Pvc Film Fills

- Color Black

- Cooling Coil Material PVC

- Warranty Yes

- Click to view more

Pvc Film Fills Price And Quantity

- 1 INR/Cubic Meter

- 50 Cubic Meter

Pvc Film Fills Product Specifications

- Pvc Film Fills

- Industrial

- Black

- Yes

- Pvc Film Fills

- PVC

Pvc Film Fills Trade Information

- 1000 Cubic Meter Per Week

- 2 Week

Product Description

PVC Film Fills are one of the most efficient filling media which is present for cooling the towers properly and effectively. These fills are made using honeycombed PVC film which ensures proper water distribution and high efficiency water to air heat transfer. These fills are best known for its quality, durability, great cooling capacity, light weighted, eco-friendly, reduces water wastages and economical to use and easy to handle. PVC Film Fills also help in reducing the fill height as well as transportation and maintenance costs. These fills require low power consumption hence less amount of energy is preferred for better cooling.

Technical Specification

| Characteristics | CD-19 |

| Primary Cooling Towers Application | Counterflow |

| Flute height | 19 mm |

| MOC | Virgin rigid PVC |

| Longitudinal pitch | 50 mm |

| UV Stabilization | White Titanium Dioxide |

| Spiral angle | 28 |

| Std. Sheet sizeL x W | 1200mm x 600mm |

| Recommended Max Fill Sheet size L x W | 1800 mm x 600 mm |

| Surface area per unit volume | 158 m/m |

| Standard Weight | 27 Kgs/m3 |

| Maximum continuous Operating temp. | 55 C |

| Standard Fill Sheet Finished Thickness (Available in 0.23mm thickness Other thickness on request) | 0.25 mm |

| Standard Followed for Material properties | CTI STD-136 |

Superior Cooling Performance

Our PVC Film Fills are specifically crafted to maximize water and air contact, optimizing the cooling process in industrial cooling towers. The high-quality black PVC material is corrosion-resistant, ensuring dependable operation and reduced maintenance.

Reliable and Guaranteed Quality

Backed by a warranty, these PVC Film Fills offer peace of mind to manufacturers and suppliers. Their robust construction helps extend the lifespan of your cooling system while maintaining consistent performance under demanding industrial conditions.

Nationwide Supply and Export

Proudly made in India, our PVC Film Fills are distributed across the country and internationally. As trusted exporters, manufacturers, and suppliers, we ensure timely delivery and professional support for diverse industrial needs.

FAQs of Pvc Film Fills:

Q: How are PVC Film Fills used in industrial cooling systems?

A: PVC Film Fills are installed within cooling towers to increase surface area for water and air contact. This enhances heat transfer, leading to more efficient cooling in industrial environments.Q: What benefits does the black color of PVC Film Fills provide?

A: The black color improves UV resistance and reduces growth of algae, maintaining the film fills integrity and minimizing cleaning frequency in cooling tower operations.Q: When should I consider replacing my PVC Film Fills?

A: Replacement is recommended if you observe reduced cooling efficiency, visible wear, or material deposits obstructing water flow, typically after several years of continuous use, depending on operating conditions.Q: Where do you export and supply PVC Film Fills from India?

A: As exporters, manufacturers, and suppliers based in India, we supply PVC Film Fills to various industrial locations domestically and worldwide, ensuring swift delivery and quality service.Q: What process is used to manufacture PVC Film Fills?

A: Our PVC Film Fills are manufactured using advanced extrusion and forming techniques to ensure consistent thickness, high durability, and optimal performance in cooling systems.Q: What is the main advantage of using PVC for cooling coil material?

A: PVC offers excellent resistance to chemicals and corrosion. This makes it a reliable choice for cooling coil material, resulting in longer service life and reduced maintenance costs.Q: How does the warranty benefit users of PVC Film Fills?

A: The warranty provides assurance of quality and reliability, covering defects in material or manufacturing. This protects your investment and ensures continued operation of your cooling system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese